STRUCTURE FACILITY

The facility is developed and manufactured in the frame of ISTC Project # 3895 “Nanometer Structures for Fuel Cells and Displays, etc.”. It is alpha-level system for industrial realization of non-contact WOS (Wave Ordered Structures) technology of periodic nano structures formation in the result of material treatment by ion beam. These periodic nano-size (10-100 nm) structures have a wide range of applications, including flat panel displays, optical electronics, clean energy technologies (solar and fuel cells, lithium batteries) and other potential areas. In particular, industrial technology of “black silicon” production may be realized such a way.

The facility is bringing together two complimentary technologies allowing for production of precise nanostructures over large area in a way that is significantly less expensive than traditional methods (such as lithography for example):

• Technology of nanorelief formation employing the self-formation phenomenon to create Wave Ordered Structures (WOS) by low-energy ion beam bombardment. Such a WOS nanorelief is used as hard etching mask to produce the required structures (as, for example, nanowire arrays, trenches, quantum sources, etc.) by means of traditional etching or ion sputtering.

• The ion beam technology adapted to formation of WOS nanorelief on large area.

The Project is realized with participation of three enterprises: LBNL (USA), D.V. Efremov Institute (St-Petersburg, Russia) and Wostec, Inc. (USA).

Basic facility subsystems and theirs parameters:

Vacuum chamber (chamber of treatment), mm d=520x900

- heating of inner surface chamber, С 80

Water-cooled stage with possibility of translation and

inclination angle change, mm 260 x 230

- maximum size of treated specimens, mm 200 x 200

- translation velocity (electric motor), mm/s 0,6 – 2,4

- maximum stage translation, mm 340

- inclination angle change (to the normal of

treatment surface), grad 35 – 65

Ion source Tamiris 400-f (Roth&Rau AG)

- ion beam length, mm 250

- ion beam wide, mm 60 - 140

- ion density, mА/сm2, up to 2,5

- ion density inhomogeneity ±5%

- ion energy, eV 500 – 3000

- plasma generation 2 x ECR 2,45 GHz, 1200 W

- ion beam neutralization Plasma Bridge Neutralizer

Vacuum and gas supply system

- fore vacuum pumping:

oil free scroll pump ISP-500 (AnestIwata), l/min 500

- high vacuum pumping:

turbo-molecular pump ТМР-1003LM (Shimadzu), l/s 1080

cryogenic pump NVK250-3,2 (NTK «Cryogenic technique»), l/s 2500

Control system

- ion source control system

- control system of the treatment chamber and ion beam parameters

System of technology supply

- closed-loop water-cooling system with cold-capacity up to 10,2 kW

|

| General view of the facilit |

|

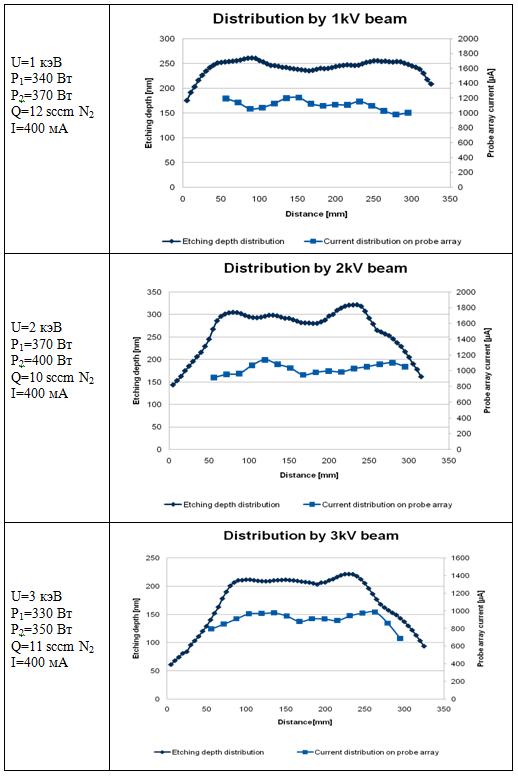

| Aggregate data of ion beam homogeneity measurements |